Industrial Robotics

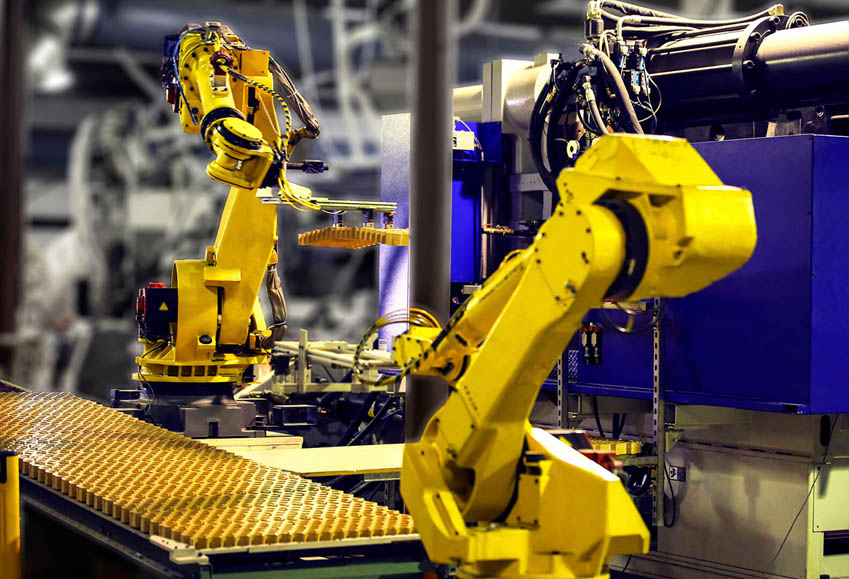

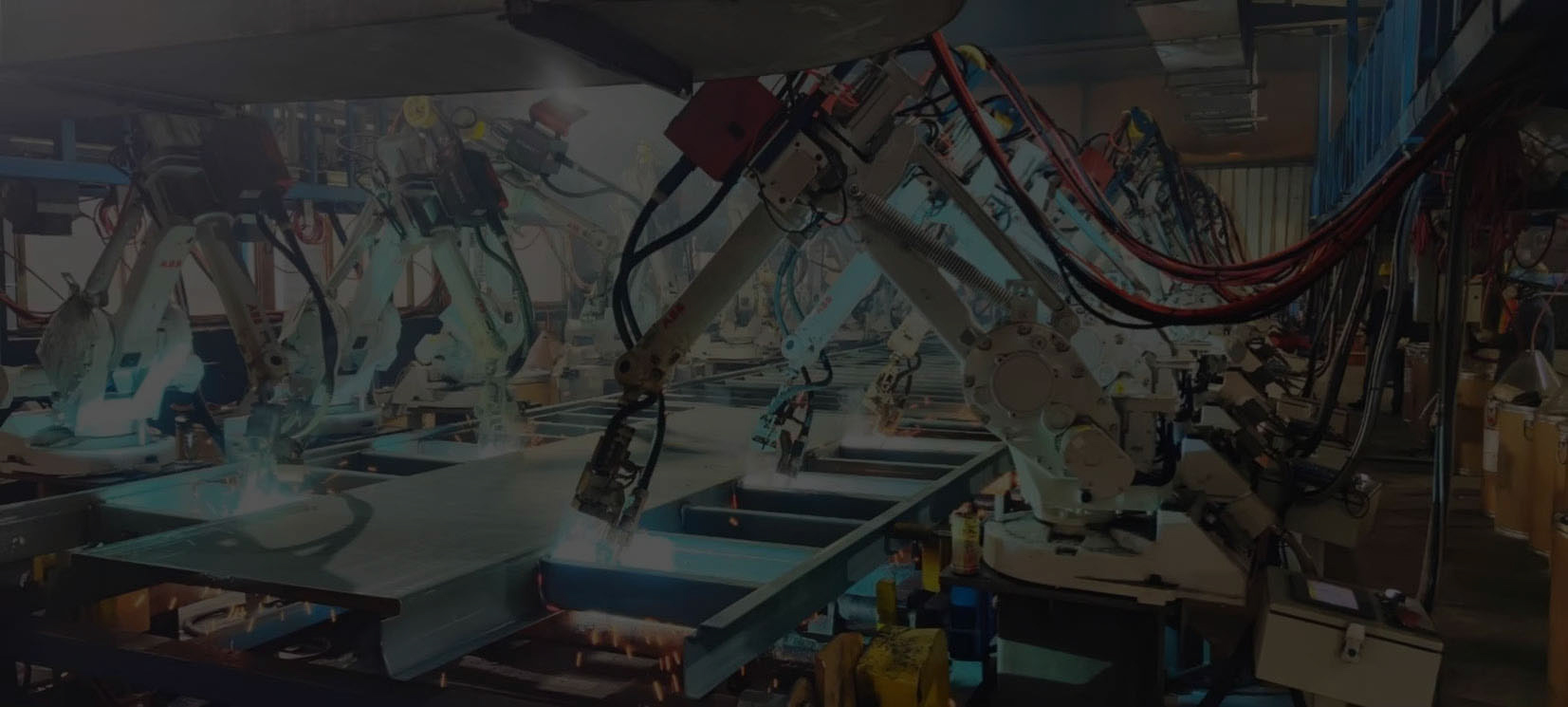

The industrial robotics market is experiencing significant growth, driven by advancements in automation and increasing demand for precision in manufacturing processes. Industries such as automotive, electronics, and metal fabrication are at the forefront, leveraging robotics to enhance productivity, improve quality, and reduce operational costs. The integration of AI and machine learning with industrial robots is transforming production lines, enabling more sophisticated, flexible, and adaptive systems. Emerging markets in Asia-Pacific, particularly China and India, are showing robust adoption rates, attributed to government initiatives and investments in smart manufacturing.

Collaborative robots, or cobots, are gaining traction due to their ability to work alongside human workers safely and efficiently. This segment is particularly attractive to small and medium-sized enterprises (SMEs) that seek automation without significant capital investment. Furthermore, the trend towards Industry 4.0 is pushing for more interconnected and intelligent robotic systems, integrating IoT devices and real-time data analytics.

.jpg)

.jpg)